How does PVC insulated wire facilitate conduit routing in confined spaces?

Release Time : 2025-09-18

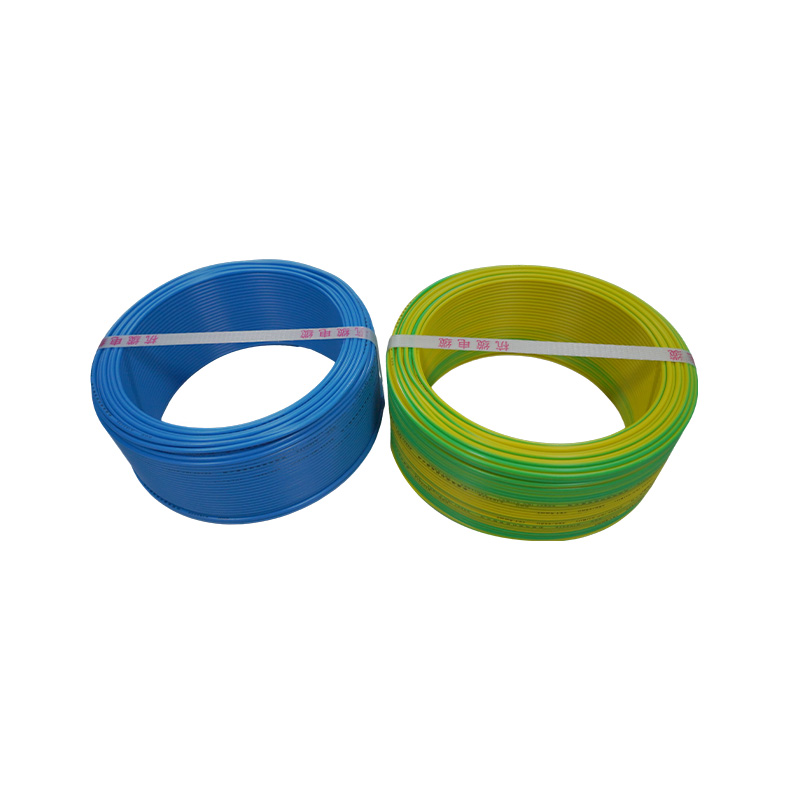

In modern electrical installations in homes, commercial buildings, and small industrial facilities, conduit routing is a standard practice for ensuring electrical safety, extending line life, and enhancing overall aesthetics. This is especially true in confined areas such as walls, ceiling mezzanines, and equipment control boxes, where wiring paths are often narrow and winding, placing higher demands on wire flexibility and ease of installation. PVC insulated wire, due to its excellent physical properties and structural design, is an ideal choice for conduit routing in confined spaces. It not only offers excellent insulation properties but also exhibits significant advantages in flexibility, outer diameter control, and surface smoothness, significantly improving wiring efficiency and construction quality.

1. Excellent Flexibility, Adapting to Complex Curves

One of the core advantages of PVC-insulated wire is its exceptional flexibility. PVC inherently possesses a certain degree of elasticity and ductility. When used as an insulating layer around a copper conductor, it can withstand repeated bending within a narrow radius without cracking or breaking. During conduit routing, wires often need to navigate multiple bends, right-angle turns, or narrow cable ducts. PVC insulation effectively absorbs stress, preventing insulation damage or conductor breakage caused by excessive bending. This flexible and easily bendable property allows installation workers to easily push or pull wires through complex PVC conduit, metal hoses, or pre-buried cable ducts, reducing jamming and resistance, significantly improving conduit routing efficiency.

2. Small and uniform outer diameter saves space and increases conduit routing success rate

In confined spaces, the inner diameter of conduit is often limited, and when routing multiple wires in parallel, the overall outer diameter is extremely stringent. PVC insulation achieves uniform thickness and controllable outer diameter through a precision extrusion process, ensuring compact overall cable dimensions. Compared to other insulation materials, PVC insulation can be made thinner while still meeting electrical safety standards, thereby reducing the outer diameter of the wire.

3. Smooth surface reduces frictional resistance

After high-temperature extrusion and cooling to set the shape, the PVC insulation achieves a smooth and delicate surface with a low coefficient of friction. During conduit threading, sliding friction occurs between the wire and the conduit wall. The smooth PVC surface effectively reduces frictional resistance, making the wire easier to pull. This low resistance significantly reduces the amount of manual pulling force required, preventing excessive force that could damage the wire or cause connectors to become loose. Some high-quality PVC wires also incorporate lubricants or undergo surface treatment in the insulation layer to further enhance sliding properties, ensuring smooth threading.

4. Stable Structure, Resistant to Compression and Deformation

PVC insulated wire is flexible and easily pliable, yet its structural strength is sufficient to withstand the compression and friction experienced during conduit threading. The insulation is tightly bonded to the conductor, resisting peeling or wrinkling. Even when squeezed alongside other wires in narrow conduits, the PVC insulation maintains its shape, preventing deformation from compressing and compromising electrical performance or increasing subsequent threading difficulties. This "flexible yet strong" property ensures the long-term reliability of the wire in complex environments.

5. Environmental Resistance Supports Long-Term Stable Operation

After conduit routing, electrical wires will remain in a closed environment for extended periods, potentially exposed to moisture, temperature fluctuations, and minor vibrations. PVC insulation offers excellent resistance to moisture, mildew, and acid and alkali, and is resistant to aging and brittleness, ensuring long-term stable operation in concealed spaces such as inside walls.

PVC insulated wire, with its excellent flexibility, compact outer diameter, smooth surface, and stable structure, is the preferred wire material for conduit routing in confined spaces. It not only reduces installation complexity and improves wiring efficiency, but also ensures the safety and durability of electrical systems. In home renovations, lighting projects, and small power equipment connections, PVC insulated wire, with its ease of routing, installation, and maintenance, silently supports the efficient operation of modern building electrical systems.

1. Excellent Flexibility, Adapting to Complex Curves

One of the core advantages of PVC-insulated wire is its exceptional flexibility. PVC inherently possesses a certain degree of elasticity and ductility. When used as an insulating layer around a copper conductor, it can withstand repeated bending within a narrow radius without cracking or breaking. During conduit routing, wires often need to navigate multiple bends, right-angle turns, or narrow cable ducts. PVC insulation effectively absorbs stress, preventing insulation damage or conductor breakage caused by excessive bending. This flexible and easily bendable property allows installation workers to easily push or pull wires through complex PVC conduit, metal hoses, or pre-buried cable ducts, reducing jamming and resistance, significantly improving conduit routing efficiency.

2. Small and uniform outer diameter saves space and increases conduit routing success rate

In confined spaces, the inner diameter of conduit is often limited, and when routing multiple wires in parallel, the overall outer diameter is extremely stringent. PVC insulation achieves uniform thickness and controllable outer diameter through a precision extrusion process, ensuring compact overall cable dimensions. Compared to other insulation materials, PVC insulation can be made thinner while still meeting electrical safety standards, thereby reducing the outer diameter of the wire.

3. Smooth surface reduces frictional resistance

After high-temperature extrusion and cooling to set the shape, the PVC insulation achieves a smooth and delicate surface with a low coefficient of friction. During conduit threading, sliding friction occurs between the wire and the conduit wall. The smooth PVC surface effectively reduces frictional resistance, making the wire easier to pull. This low resistance significantly reduces the amount of manual pulling force required, preventing excessive force that could damage the wire or cause connectors to become loose. Some high-quality PVC wires also incorporate lubricants or undergo surface treatment in the insulation layer to further enhance sliding properties, ensuring smooth threading.

4. Stable Structure, Resistant to Compression and Deformation

PVC insulated wire is flexible and easily pliable, yet its structural strength is sufficient to withstand the compression and friction experienced during conduit threading. The insulation is tightly bonded to the conductor, resisting peeling or wrinkling. Even when squeezed alongside other wires in narrow conduits, the PVC insulation maintains its shape, preventing deformation from compressing and compromising electrical performance or increasing subsequent threading difficulties. This "flexible yet strong" property ensures the long-term reliability of the wire in complex environments.

5. Environmental Resistance Supports Long-Term Stable Operation

After conduit routing, electrical wires will remain in a closed environment for extended periods, potentially exposed to moisture, temperature fluctuations, and minor vibrations. PVC insulation offers excellent resistance to moisture, mildew, and acid and alkali, and is resistant to aging and brittleness, ensuring long-term stable operation in concealed spaces such as inside walls.

PVC insulated wire, with its excellent flexibility, compact outer diameter, smooth surface, and stable structure, is the preferred wire material for conduit routing in confined spaces. It not only reduces installation complexity and improves wiring efficiency, but also ensures the safety and durability of electrical systems. In home renovations, lighting projects, and small power equipment connections, PVC insulated wire, with its ease of routing, installation, and maintenance, silently supports the efficient operation of modern building electrical systems.