Why is general-purpose rubber-sheathed flexible cable suitable for connecting frequently mobile electrical equipment?

Release Time : 2025-10-16

In modern industrial production, construction, agricultural operations, and various temporary power-using scenarios, many electrical devices are frequently moved, repeatedly dragged, or continuously operated in complex environments. From welding machines and cutting machines to mobile lighting fixtures, from port lifting equipment to agricultural irrigation pumps, these devices rely on a special type of cable—general-purpose rubber-sheathed flexible cable—to power them. Its popularity as a preferred choice for mobile electrical connections stems not only from its basic electrical conductivity but also from its overall structural design and material properties, which perfectly meet the core requirements of "dynamic use." Designed not for static wiring but to withstand frequent bending, stretching, friction, and environmental impact, this cable provides a flexible link between power and mobile devices.

The core advantage of general-purpose rubber-sheathed flexible cable lies primarily in its exceptional flexibility. Unlike conventional rigid cables, its conductors are made of multiple, tightly twisted strands of extremely fine copper wire. This structure significantly improves the conductor's bending properties, ensuring uniform internal stress distribution during repeated flexing, making it less susceptible to metal fatigue or strand breakage. Even when coiled in confined spaces, threaded through pipes, or moved with equipment, the cable bends smoothly without damaging its internal structure. This "soft but not fragile" characteristic ensures continuous and secure power transmission during long-term dynamic use.

Another key factor is the outer sheath, made of natural or synthetic rubber. Rubber's inherent elasticity, wear resistance, and tear resistance effectively withstand the surface abrasion caused by construction site debris, mechanical impact, oil erosion, and frequent dragging. Compared to rigid sheaths like PVC, rubber remains flexible at low temperatures and does not become brittle or crack due to the cold. It also exhibits excellent stability at high temperatures and is not susceptible to softening or deformation. This wide temperature range ensures reliable operation in outdoor environments with seasonal fluctuations and significant day-night temperature swings.

Furthermore, the rubber sheath offers excellent sealing and environmental resistance. It effectively blocks the intrusion of external media such as moisture, dust, and oil, protecting the internal insulation and conductors from corrosion and the risk of short circuits. Even in damp basements, muddy construction sites, or areas being cleaned by water, the cable maintains excellent insulation properties, preventing electrical leakage and electric shock. This protective capability ensures safe power supply in complex and changing field environments.

General-purpose rubber-sheathed flexible cables typically feature a layered construction. The conductors are wrapped in a highly elastic insulation layer. Multi-core cables also feature a filler layer to maintain a round cross-section, and a thick, tough rubber sheath forms the outermost layer. This multi-layered protection system works synergistically to enhance the cable's overall strength while also strengthening its tensile, compressive, and torsional resistance. Even when pulled or squeezed during equipment movement, the cable maintains its structural integrity and avoids internal damage.

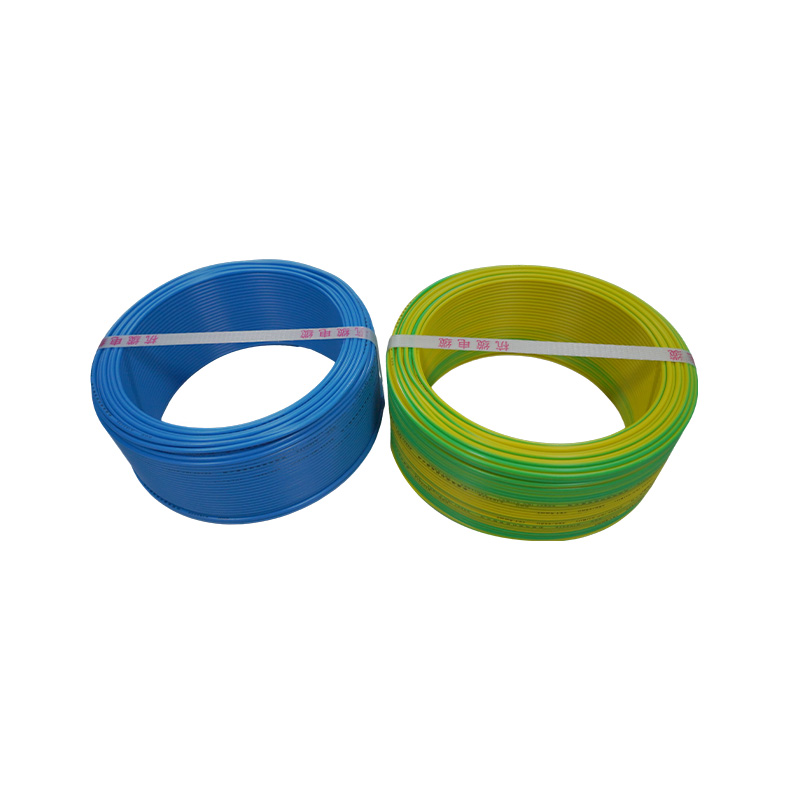

More importantly, this cable is designed with practical convenience and safety in mind. Its smooth and flexible outer sheath facilitates manual dragging and coiling for storage. Clear color coding, with multi-core cables distinguished by color or numbering, reduces wiring errors. The cable is relatively lightweight, reducing operator workload. Furthermore, the rubber material itself possesses a certain degree of flame retardancy, making it less likely to ignite and spread when exposed to brief periods of high temperature or electric arcs, enhancing operational safety.

Ultimately, the value of general-purpose rubber-sheathed flexible cable lies not in the amount of current it transmits, but in its ability to maintain stable power supply despite constant movement and challenges. Like a resilient "lifeline," it connects power to dynamic equipment, supporting the smooth operation of countless temporary, mobile, and high-intensity operations. Whether illuminating a late-night construction site or sparking welding sparks at a repair site, every bend and drag of the cable silently fulfills its promise of reliability and safety. It is this design philosophy, born for mobility, that makes it an irreplaceable core component for connecting frequently moving electrical equipment.

The core advantage of general-purpose rubber-sheathed flexible cable lies primarily in its exceptional flexibility. Unlike conventional rigid cables, its conductors are made of multiple, tightly twisted strands of extremely fine copper wire. This structure significantly improves the conductor's bending properties, ensuring uniform internal stress distribution during repeated flexing, making it less susceptible to metal fatigue or strand breakage. Even when coiled in confined spaces, threaded through pipes, or moved with equipment, the cable bends smoothly without damaging its internal structure. This "soft but not fragile" characteristic ensures continuous and secure power transmission during long-term dynamic use.

Another key factor is the outer sheath, made of natural or synthetic rubber. Rubber's inherent elasticity, wear resistance, and tear resistance effectively withstand the surface abrasion caused by construction site debris, mechanical impact, oil erosion, and frequent dragging. Compared to rigid sheaths like PVC, rubber remains flexible at low temperatures and does not become brittle or crack due to the cold. It also exhibits excellent stability at high temperatures and is not susceptible to softening or deformation. This wide temperature range ensures reliable operation in outdoor environments with seasonal fluctuations and significant day-night temperature swings.

Furthermore, the rubber sheath offers excellent sealing and environmental resistance. It effectively blocks the intrusion of external media such as moisture, dust, and oil, protecting the internal insulation and conductors from corrosion and the risk of short circuits. Even in damp basements, muddy construction sites, or areas being cleaned by water, the cable maintains excellent insulation properties, preventing electrical leakage and electric shock. This protective capability ensures safe power supply in complex and changing field environments.

General-purpose rubber-sheathed flexible cables typically feature a layered construction. The conductors are wrapped in a highly elastic insulation layer. Multi-core cables also feature a filler layer to maintain a round cross-section, and a thick, tough rubber sheath forms the outermost layer. This multi-layered protection system works synergistically to enhance the cable's overall strength while also strengthening its tensile, compressive, and torsional resistance. Even when pulled or squeezed during equipment movement, the cable maintains its structural integrity and avoids internal damage.

More importantly, this cable is designed with practical convenience and safety in mind. Its smooth and flexible outer sheath facilitates manual dragging and coiling for storage. Clear color coding, with multi-core cables distinguished by color or numbering, reduces wiring errors. The cable is relatively lightweight, reducing operator workload. Furthermore, the rubber material itself possesses a certain degree of flame retardancy, making it less likely to ignite and spread when exposed to brief periods of high temperature or electric arcs, enhancing operational safety.

Ultimately, the value of general-purpose rubber-sheathed flexible cable lies not in the amount of current it transmits, but in its ability to maintain stable power supply despite constant movement and challenges. Like a resilient "lifeline," it connects power to dynamic equipment, supporting the smooth operation of countless temporary, mobile, and high-intensity operations. Whether illuminating a late-night construction site or sparking welding sparks at a repair site, every bend and drag of the cable silently fulfills its promise of reliability and safety. It is this design philosophy, born for mobility, that makes it an irreplaceable core component for connecting frequently moving electrical equipment.