How does PVC insulated wire effectively prevent current leakage and ensure household electrical safety?

Release Time : 2025-12-11

In modern homes, electrical wires act like invisible blood vessels, silently transmitting electricity and supporting the daily operation of lighting, appliances, and even smart devices. However, if current deviates from its conductor path, it can not only cause equipment malfunctions but also potentially lead to serious safety accidents such as electric shock or fire. PVC insulated wire, as the most common insulating material in household appliances and lighting circuits, uses its unique physical and electrical properties to build a reliable safety barrier between the conductor and the outside environment, effectively preventing current leakage and protecting the electrical safety of countless households.

The core function of PVC insulated wire lies in its excellent electrical insulation properties. As a high-molecular polymer, PVC has almost no freely moving electrons or ions and extremely high resistivity, effectively preventing current from escaping from the metal conductor to the external environment. When the wire is energized, regardless of the voltage, the PVC layer firmly "locks in" the current, ensuring it flows strictly along the copper or aluminum conductor, preventing accidental circuits from forming due to contact with walls, metal supports, or people. This insulating ability is not temporary but remains stable over long-term use—even under humidity, high temperatures, or slight mechanical stress, PVC maintains its dielectric strength, preventing insulation failure due to aging.

Besides its basic insulation function, PVC material also possesses excellent density and encapsulation properties. During manufacturing, molten PVC evenly coats the conductor surface, forming a continuous, seamless protective layer upon cooling. This layer is pore-free and crack-free, eliminating the possibility of moisture, dust, or corrosive gases intruding into the conductor. Once a conductor is exposed to a humid environment, it is highly susceptible to oxidation or electrolysis, which can reduce insulation performance and even cause short circuits. A complete PVC insulation layer acts like a "sealed coat," completely isolating the conductor from the external environment and eliminating the risk of leakage at its source.

Furthermore, PVC's flame-retardant properties add an extra layer of protection for home safety. Ordinary PVC formulations contain chlorine, which releases free radicals that inhibit combustion when exposed to fire, giving the material self-extinguishing properties—meaning it quickly stops burning after the flame is removed, preventing the fire from spreading along the wires. This characteristic is particularly important when circuit overload or short circuits generate high temperatures, effectively slowing the spread of fire and buying valuable time for evacuation and firefighting. Some high-end products also use low-smoke halogen-free modified PVC, reducing the release of toxic fumes during combustion and further enhancing survival safety in a fire.

Furthermore, the mechanical properties of PVC insulated wire are equally crucial. It possesses a certain degree of flexibility, facilitating installation through conduit and bending, while also exhibiting sufficient abrasion and tear resistance, making it less susceptible to scratches from tools, punctures from nails, or damage from furniture during installation or later use. Once the insulation layer is damaged, the conductor is exposed, and the risk of leakage increases dramatically. High-quality PVC wires are designed with the physical challenges of daily use in mind, ensuring that insulation integrity is maintained throughout their entire lifespan.

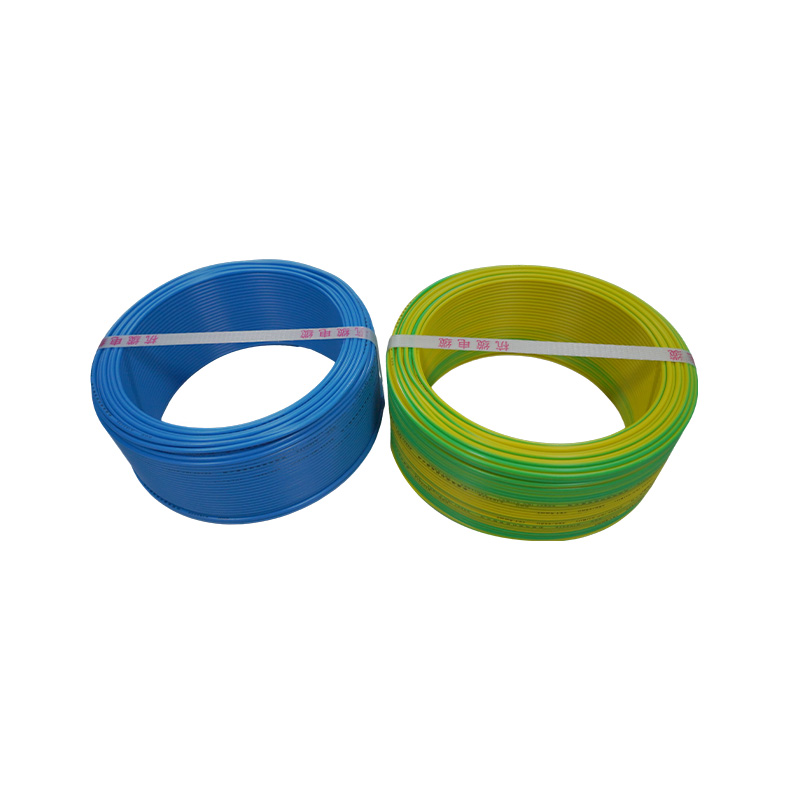

It is worth mentioning that PVC insulated wire also enhances safety identification through a color-coding system. The live wire, neutral wire, and ground wire use standard colors such as red, blue, and yellow-green, respectively, helping electricians quickly and accurately connect wires and avoiding equipment damage or personal injury due to incorrect connections. While seemingly small, these visual guidelines are an indispensable part of a safety system.

In short, the effectiveness of PVC insulated wire in preventing current leakage is not due to a single property, but rather the result of the combined effects of electrical insulation, a dense structure, flame retardancy, mechanical durability, and standardized design. Though silent, it performs the most basic and crucial safety mission day after day—ensuring that current only travels where it should, providing peace of mind for household electricity use. Behind every lit light and every operating appliance, this seemingly ordinary layer of plastic is an invisible shield protecting life and property.

The core function of PVC insulated wire lies in its excellent electrical insulation properties. As a high-molecular polymer, PVC has almost no freely moving electrons or ions and extremely high resistivity, effectively preventing current from escaping from the metal conductor to the external environment. When the wire is energized, regardless of the voltage, the PVC layer firmly "locks in" the current, ensuring it flows strictly along the copper or aluminum conductor, preventing accidental circuits from forming due to contact with walls, metal supports, or people. This insulating ability is not temporary but remains stable over long-term use—even under humidity, high temperatures, or slight mechanical stress, PVC maintains its dielectric strength, preventing insulation failure due to aging.

Besides its basic insulation function, PVC material also possesses excellent density and encapsulation properties. During manufacturing, molten PVC evenly coats the conductor surface, forming a continuous, seamless protective layer upon cooling. This layer is pore-free and crack-free, eliminating the possibility of moisture, dust, or corrosive gases intruding into the conductor. Once a conductor is exposed to a humid environment, it is highly susceptible to oxidation or electrolysis, which can reduce insulation performance and even cause short circuits. A complete PVC insulation layer acts like a "sealed coat," completely isolating the conductor from the external environment and eliminating the risk of leakage at its source.

Furthermore, PVC's flame-retardant properties add an extra layer of protection for home safety. Ordinary PVC formulations contain chlorine, which releases free radicals that inhibit combustion when exposed to fire, giving the material self-extinguishing properties—meaning it quickly stops burning after the flame is removed, preventing the fire from spreading along the wires. This characteristic is particularly important when circuit overload or short circuits generate high temperatures, effectively slowing the spread of fire and buying valuable time for evacuation and firefighting. Some high-end products also use low-smoke halogen-free modified PVC, reducing the release of toxic fumes during combustion and further enhancing survival safety in a fire.

Furthermore, the mechanical properties of PVC insulated wire are equally crucial. It possesses a certain degree of flexibility, facilitating installation through conduit and bending, while also exhibiting sufficient abrasion and tear resistance, making it less susceptible to scratches from tools, punctures from nails, or damage from furniture during installation or later use. Once the insulation layer is damaged, the conductor is exposed, and the risk of leakage increases dramatically. High-quality PVC wires are designed with the physical challenges of daily use in mind, ensuring that insulation integrity is maintained throughout their entire lifespan.

It is worth mentioning that PVC insulated wire also enhances safety identification through a color-coding system. The live wire, neutral wire, and ground wire use standard colors such as red, blue, and yellow-green, respectively, helping electricians quickly and accurately connect wires and avoiding equipment damage or personal injury due to incorrect connections. While seemingly small, these visual guidelines are an indispensable part of a safety system.

In short, the effectiveness of PVC insulated wire in preventing current leakage is not due to a single property, but rather the result of the combined effects of electrical insulation, a dense structure, flame retardancy, mechanical durability, and standardized design. Though silent, it performs the most basic and crucial safety mission day after day—ensuring that current only travels where it should, providing peace of mind for household electricity use. Behind every lit light and every operating appliance, this seemingly ordinary layer of plastic is an invisible shield protecting life and property.